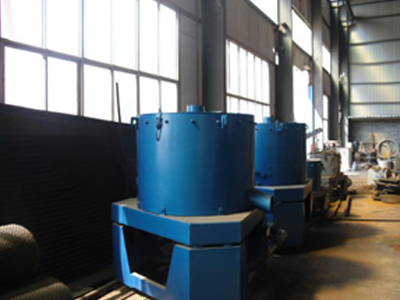

[Introduction] A gravity separation equipment for recovering individual gold from placer gold, vein gold and polymetallic ore

[Capability] 1-180 t/h

[Application] Recovery of monomer gold from placer gold, vein gold and polymetallic ore, it can replace mercury plate.

[Improvement] Higher enrichment ratio (up to several thousand times).

Chat With Us

Chat With Us

Leave Message

Leave Message

1.Small area, easy to operate and maintain.

2.Intermittent production, stable operation and automatic concentrate drainage.

3.Higher enrichment ratio (up to several thousand times) can be obtained by prolonging the interruption time.

4.The recovery rate of fine-grained gold can reach over 96%.

Structure

The drum of the centrifugal concentrator rotates at high speed, and the pulp is fed to the inner wall of the drum from the feeder through the feeding nozzle in two places. Under the action of centrifugal force, the heavy minerals deposit on the inner wall of the drum and rotate with the drum. The light minerals in the pulp rotate with the drum at a certain differential speed. In the process of rotation, they rotate from the feeding end along the slope of the drum to the discharging end with a certain spiral angle, and discharged through the discharging separator at the end, namely tailings.

|

Model |

19 Type |

30 Type |

60 Type |

70 Type |

80 Type |

100 Type |

120 Type |

|

Capacity t/h |

0.25-1 |

2-8 |

10-40 |

25-30 |

35-60 |

80-120 |

120-180 |

|

Feeding Size mm |

0-3 |

0-4 |

0-6 |

0-6 |

0-6 |

0-6 |

0-6 |

|

Feeding Density % |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

0-50 |

|

Water Consumption t/h |

1.5-2 |

4-6 |

10-15 |

17-25 |

20-30 |

40-60 |

70-80 |

|

Production kg/time |

2-3 |

10-20 |

30-40 |

50-60 |

60-70 |

70-80 |

110-120 |

|

Power kw |

0.75 |

1.5 |

5.5 |

7.5 |

11 |

18.5 |

22 |

|

Revolution r/min |

800 |

600 |

460 |

430 |

400 |

360 |

360 |

|

Water Pressure Mpa |

0.04 |

0.12 |

0.25 |

0.3 |

0.35 |

0.4 |

0.5 |

|

Dimension m |

0.8×0.8×0.8 |

1.2×1.2×1.3 |

2 ×1.7×1.8 |

2.1 ×1.7×2 |

2.3×1.8×2.2 |

2.5×2.0×2.4 |

2.7 ×2.2×2.6 |

|

Weight kg |

145 |

400 |

1300 |

1900 |

2000 |

2500 |

3000 |