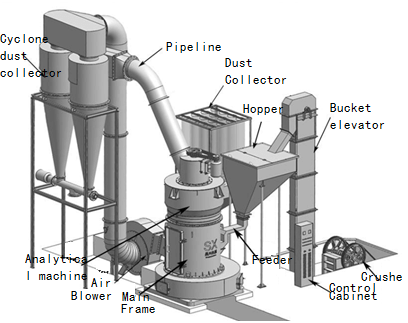

[Introduction] A mill with independent production system.

[Capability] 3-22t/h

[Application] Various non-flammable and non-explosive mineral materials with hardness below 9.3 mohs and humidity below 6%, such as cement, talc, feldspar, quartz, slag, mica, calcite, limestone, barite, potassium sulfate, bentonite, etc.

[Improvement] Unique air self-circulating system, equipped with advanced dust collector, the grinding roller assembly is connected with high-pressure spring through tie rod, which avoids the loss of large material to equipment. The elastic connection between the main engine and the flour separator reduces vibration and noise and improves the service life of the equipment.

Chat With Us

Chat With Us

Leave Message

Leave Message

Material is evenly and continuously fed into the machine for grinding. The grinded powder is taken out by the circulating air flow of the blower and classified by the classifier above the raymond mill. The powder conforms to the specifications goes into the cyclone dust collector. The air flow is flowed into the blower by the return duct at the upper end of the cyclone receiver. The whole air system is closed cycle, and most of the air flow is in the negative pressure state. Because the grinded material contains water, it evaporates into gas during grinding and leaks into the air duct under negative pressure, which leads to the increase of air flow in the circulating air duct. The increased air flow is introduced into the dust removal box from the residual air duct of the blower and the main engine, and a number of fine powder brought with the air flow is collected in the dust removal box, and the gas is discharged into the atmosphere from the exhaust pipe.

|

model |

3R-2615 |

3R-2715 |

4R-3216 |

5R-4121 |

6R-4525 |

6R-4628 |

|

|

Grinding rod |

quantity |

3 |

3 |

4 |

5 |

6 |

6 |

|

Diameter mm |

260 |

270 |

320 |

410 |

450 |

460 |

|

|

Height mm |

150 |

150 |

160 |

210 |

250 |

280 |

|

|

Grinding ring |

Inner Diameter (mm) |

780 |

830 |

970 |

1280 |

1600 |

1900 |

|

Height mm |

150 |

150 |

160 |

210 |

250 |

280 |

|

|

Max feeding size mm |

≤20 |

≤20 |

≤25 |

≤30 |

≤35 |

≤45 |

|

|

If the particle is bigger than the biggest feeding size, the jaw crusher is needed. |

|||||||

|

Finished product mm |

1.6-0.045mm |

||||||

|

Main motor power kw |

18.5 |

22 |

37 |

75 |

132 |

200 |

|

|

Capacity tph |

0.9-2.5 |

1.2-2.8 |

1.8-4.5 |

5-10 |

10-22 |

18-35 |

|

|

Weight T |

4.8 |

6.5 |

13.2 |

25.7 |

43 |

68.5 |

|