[Introduction] Equipment for separating light and heavy minerals by asymmetric reciprocating motion of table surface.

[Capability] 0.1-1.8 t/h

[Application] It can be used in different operations, such as roughing, cleaning and sweeping, to separate coarse sand (2-0.5mm), fine sand (0.5-0.074mm), slime (-0.074) and other different grain classes. When treating tungsten, tin and other ores, the effective recovery particle size range is 2-0.22mm. It can also be used to separate iron and manganese ores.

[Improvement] The stroke can be adjusted by changing the position of the sliding head on the rocker arm, and the stroke can be adjusted by the belt pulley of the smooth motor.

Chat With Us

Chat With Us

Leave Message

Leave Message

Advantages

Structure

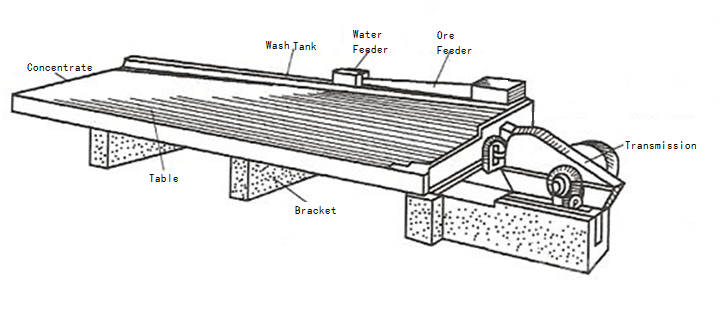

Shaking table separation is realized under the action of the table surface and transverse flow. The groove on the bed surface is longitudinal and nearly perpendicular to the direction of water flow. Eddy current forms in the groove when water flows transversely. The combined action of eddy current and table surface shaking can loosen the ore sand layer and stratify it according to density. Heavy minerals turn to the lower layer and light minerals turn to the upper layer.

This process is called a separation layer, and light minerals are subjected to the upper layer. The water flow has a greater impulse, while the lower heavy ore particles are subject to a smaller impulse, so the transverse velocity of light ore particles on the table surface is greater than that of heavy ore particles on the table surface. Longitudinally, the differential motion of the table surface not only promotes the loose stratification of the ore-sand table, but also makes the heavy ore particles move forward along the longitudinal direction at a larger speed, and the light ore particles move forward at a smaller speed.

The direction of mineral particles depends on the synthesis speed of longitudinal and transverse velocities. Heavy minerals have smaller transverse velocity and larger longitudinal velocity, light minerals have larger transverse velocity and smaller longitudinal velocity. Applying the parallelogram rule to synthesize the longitudinal and transverse velocity, we can see that the combined velocity of heavy minerals is biased towards the concentrate discharging end of the shaker, light minerals towards the tailings side of the shaker, and medium-density particles are located between the two.

Technical Parameter

|

Model |

Coarse Table Surface |

Fine Table Surface |

Groove Table Surface |

|

Table Dimension(mm) |

4436X1825X1536 |

||

|

Stroke(mm) |

16~22 |

10~16 |

10~16 |

|

Frequence(r/min) |

240~290 |

300~320 |

330~340 |

|

Water Consumption(t/h) |

190 |

80 |

50 |

|

Capacity(t/h) |

30 |

8 |

8 |

|

Feeding Size(mm) |

2~0.2 |

0.5 ~0.037 |

0.074~0.019 |

|

Pulp Density(%) |

20~25 |

15~20 |

15~20 |

|

Inclination Angle(° ) |

2°30″ |

1°50″ |

0°45″ |

|

Dimension(mm) |

5454X1825X1242 |

||

|

Power(kw) |

1.5 |

||

|

Weight(kg) |

1012 |

||